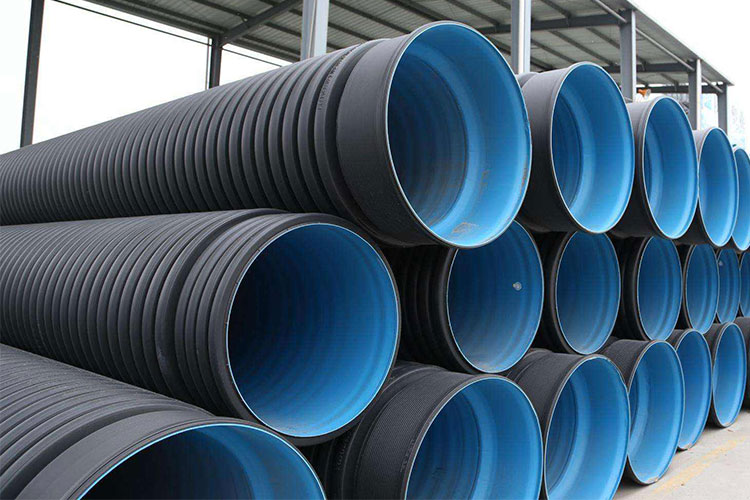

Aluminum Mould Double Wall Corrugated Pipe Extrusion Line

Big Size Drain Outlet Double Wall Corrugated Pipe Machine

Aluminum pipe forming mould, specializing in the production of large diameter pipe. Through the overall optimization design of the waveform structure, can achieve the perfect combination of high ring stiffness and low. The forming machine adopts the powerful water-cooled and air-cooled corrugated forming system, which can ensure the high production speed during continuous production.

Main Features

1. Suitable to produce PVC, PE, PP, HDPE, LDPE pipe extrusion.

2. Raw Material: PP PE PVC granule.

3. Max. Capacity: 200kg/h.

4. Mainly includes: Screw Extruder, Forming Machine, Forming Module, Cutting Machine, Stacker, Production Line Control System.

5. Supply technical service, formula guide and staple raw material purchase.

2. Raw Material: PP PE PVC granule.

3. Max. Capacity: 200kg/h.

4. Mainly includes: Screw Extruder, Forming Machine, Forming Module, Cutting Machine, Stacker, Production Line Control System.

5. Supply technical service, formula guide and staple raw material purchase.

Our Advantages

1. With the adjustment of pads, wall thickness adjustable.

2. Combined nose, reasonable structure, uniform distribution of flow channel, to ensure a smooth extrusion.

3. Stereotyped use of high-quality stainless steel water jacket materials, materials, through a complicated shape, and cold roll annealing process to ensure the processing performance and physical performance.

2. Combined nose, reasonable structure, uniform distribution of flow channel, to ensure a smooth extrusion.

3. Stereotyped use of high-quality stainless steel water jacket materials, materials, through a complicated shape, and cold roll annealing process to ensure the processing performance and physical performance.

Main Technique Parameter

| Model | FW300 | FW500 | FW800 | FW1000 |

| Pipe diameter (mm) | DN/ID 100-300mm | DN/ID 150-500mm | DN/ID 200-800mm | DN/ID 250-1000mm |

| Forming machine model | FW-300 | FW-500 | FW-800 | FW-1000 |

| Max Product speed | 6.5 m/min | 6m/min | 3.5 m/min | 2m/min |

Electric Parts

SIMENS Motor

ABB Frequency Converter

OMRON Temperature Control

Guomao Gear Reducer

Service

Pre-Sales Service

* online Inquiry and consulting support. 24 hours

* Sample testing support.

* View our Factory.

* whole manufacturing process traceable

* online Inquiry and consulting support. 24 hours

* Sample testing support.

* View our Factory.

* whole manufacturing process traceable

After-Sales Service

* Field installation, commissioning , operation training.

* Engineers available to service machinery overseas.

* Free spare parts.

* online service: 24 hours

* Field installation, commissioning , operation training.

* Engineers available to service machinery overseas.

* Free spare parts.

* online service: 24 hours

Packing & Deliery

Stretch Film Packaging

Wooden Box Plywood Packaging

Customized Packaging